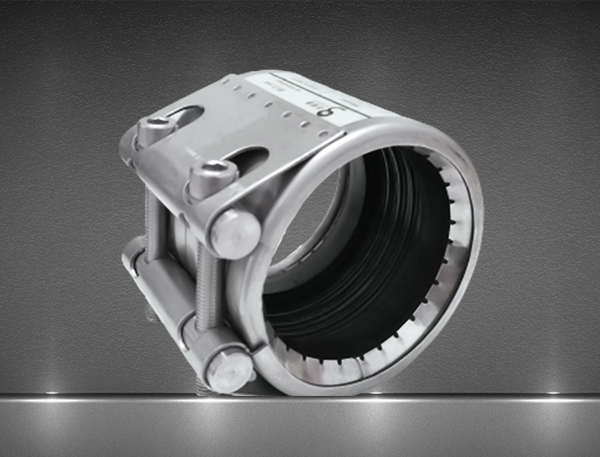

Yakasimbiswa yakadziviswa kudzora coupling

Iyo BRIP-Z ndiyo yakajairwa axial inodzoreredza kupokana neakasimbiswa yemukati mamiriro kuitira kuti evatakure kumanikidza. Mhete mbiri dzinorwadza dzinogona kuruma mumapipi maviri uye kudzivirira kubva mukukwevera kure.

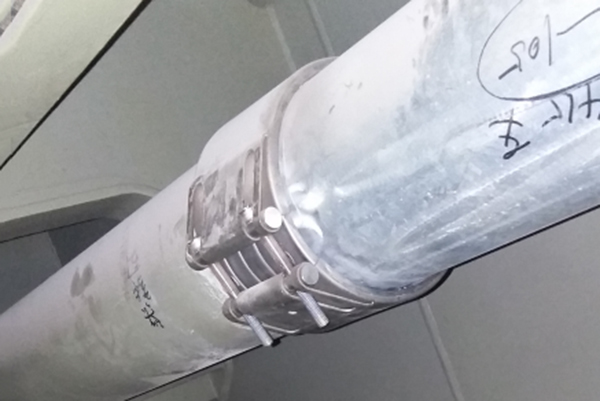

Inokodzera Pipes od φ30-φ168.3mm

Inokodzera mapepa emapepa: kabhoni simbi, simbi yesimbi, mhangura, cunofer, cunffer uye ductle iron, GRP, yakawanda mapurasitiki uye zvimwe zvinhu.

Kumanikidzwa kusvika 64bar

Grip-z inosimbiswa pakubata kweGRIP-G. Iva nekuita kwakafanana kwekubata-g uye nekumanikidzwa kwepamusoro. Two anchor rings have progressive anchoring effect, it is easy on pipes, as pressure increased, so does the gripping effect. GRIP-Z offers high levels of security by locking pipes together under pressure. GRIP-Z working pressure up to 64 bar. Temperature range: -30℃ up to 180℃, material in SS304, SS316 and SS316TI. It suitable for most applications in building construction, civil engineering, power, machinery component, shipbuilding, offshore industries, industrial process pipe work and others.

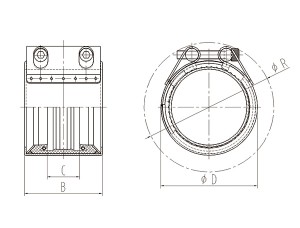

Grip-z technical parameter

Grip-z zvinyorwa kusarudzwa

| Zvinhu / zvikamu | V1 | V2 | V3 | V4 | V5 | V6 |

| Casing | Aisi 304 | Aisi 316L | Aisi 316ti | Aisi 304 | ||

| Bolts | Aisi 316L | Aisi 316L | Aisi 316L | Aisi 4135 | ||

| Mabara | Aisi 316L | Aisi 316L | Aisi 316L | Aisi 4135 | ||

| Ancharing rin'i | Aisi 301 | Aisi 301 | Aisi 301 | Aisi 301 | ||

| Strip Insert (Inesarudzo) | Aisi 301 | Aisi 301 | Aisi 301 | Aisi 301 |

Zvinhu zve rabha gasket

| Zvinhu zvechisimbiso | Media | Tembiricha |

| Epdm | Mhando dzese dzemvura, marara emvura, mhepo, solids uye makemikari zvigadzirwa | -30 ℃ kusvika ku + 120 ℃ |

| NBR | Mvura, gasi, mafuta, mafuta uye mamwe hydrocanbons | -30 ℃ UPTO + 120 ℃ |

| MVq | Yakanyanya kupisa mvura, oxygen, ozone, mvura uye zvichingodaro | -70 ℃ kusvika + 260 ℃ |

| FPM / FKM | Ozone, oxygen, Acids, gasi, mafuta uye mafuta (chete neTrip quiner) | 95 ℃ kusvika ku + 300 ℃ |

Zvakanakira Zvekuita Koriplings

1. Kushandiswa kwenyika

Inoenderana neye chero tsika yekubatanidza system

Anopinda mapipi ezvimwe zvinhu zvakafanana kana zvisina kujairika

Nekukurumidza uye nyore kugadziriswa kwe pombi dzakakuvadzwa pasina kuvhiringidza kwebasa

2.Vakafukidzwa

Kushushikana-kusununguka, zvinoshanduka pombi yakabatana

Inopa kufambisa kweiyo yexial uye angular deflection

Kumanikidzwa-kuramba uye kusvetuka-chiratidzo kunyange neyesacuraturate pombi musangano

3.Easy kubata

Zvinokatyamadza uye kudzoreredza

Kugadziriswa kwemahara uye kunetsa kusununguka

Hapana nguva yekudyara nguva yekudyara uye yakakodzera basa

Easy Kuisa tekinoroji

4.Vano

Kufambira mberi kusungwa kwemhedzisiro

Kufambira mberi kunokanganisa

Corrosion inopesana uye tembiricha inodzivirira

Kunetseka kwakanaka kumakemikari

Nguva yakareba yebasa

5.space-yekuchengetedza

Compact dhizaini yeSpace-Kuchengetedza kuiswa kwePIPES

Kurema uremu

Inoda nzvimbo shoma

6.fast uye yakachengeteka

Kuisirwa nyore, hapana moto kana kuputika njodzi panguva yekuisirwa

Hapana muripo wekudzivirira matanho

Inobata vibration / oscillations